The Importance Of Welding Filter And Hood Positioning In Fume Extraction

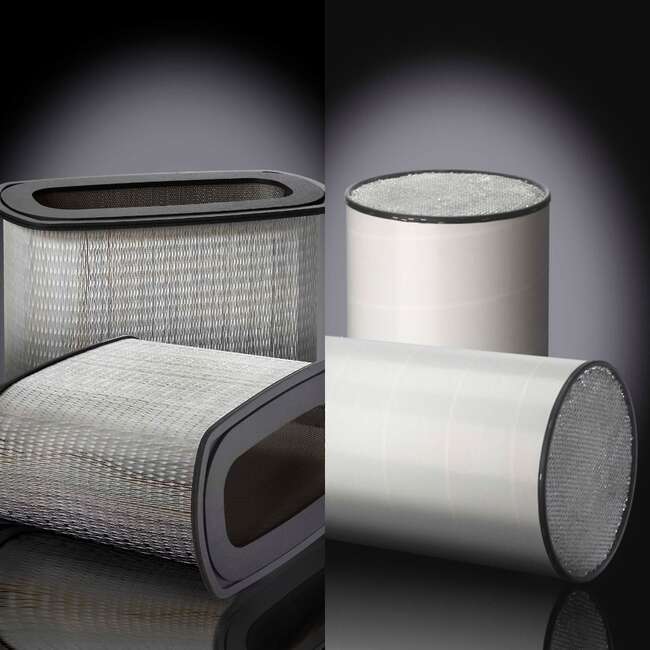

Industrial filters serve a wide variety of purposes and have myriad features according to their construction. One such filter is the welding filter. Also known as a welding fume extractor, this type of filter is important for removing any gases generated during the industrial manufacturing process. This blog explores the importance of this welding filter and how hood positioning plays a key role in its overall performance.

Why Are Welding Filters Important?

Welding filters are important in two major ways:

- Protecting Workers: The welding process releases a large amount of toxic gases made of several metal oxides, including arsenic, manganese, lead, and chromium. Inhaled, all these gases are extremely hazardous to workers. At the very least, they can lead to eye irritation, and at the extreme, they can lead to the development of specific types of cancers.

- Affecting Product Quality: Welding fumes also tend to settle on work surfaces in a facility. This can compromise the overall quality of the manufactured product. Thus, it's vital to have a proper welding filter and filter element.

Role Of Hood Positioning In Fume Extraction

To ensure the most effective removal of toxic welding fumes, it is important to remove them as close to the source as possible. This means that the distance between the weld and the welding filter should be minimal. That is where a hood comes in. For the best results, the welding extraction hood must be placed as close to the weld arc as possible. Quality welding filters have provisions to attach this fume extraction hood to them with the aid of mechanical arms or some other mechanism.

Therefore, apart from the type of welding, the material being welded, and ventilation, accessories such as an extraction hood and its positioning also play a major role in creating a safe work environment for welders.

To learn more about the different types of industrial filters and filter elements, look no further than Dynamic Filtration Ltd. Manufacturers of various types of industrial filters such as moulded-end filters, sewn-end filters, pleated air filters, custom filters, welding filters, panel filters, inlet-type filters, and more, we back the quality of our products with our expert customer service. For more information on our products, contact us at 519-886-0749 today.