5 Core Components Of A Welding Filter

Industrial filters are highly versatile in terms of features and applications. Among the different types of air filters available today, welding filters emerge as one of the most specialized ones. Their importance in removing harmful welding fumes and particles in industrial setups is well documented. However, what are some of the core components of a welding filter? This blog explores this question in detail.

Exploring Core Components Of A Welding Filter

Hood Or Arm

This is placed closest to the welding spot or arc to capture the particles as quickly as possible. It can feature an adjustable hood or arm that can be set to accommodate different angles and regions.

Ductwork

The role of the welding hood is to capture the particles as quickly as possible. However, the fumes still have to reach the filter unit for optimal filtration. This is done with the aid of appropriate ductwork that transfers the toxic fumes from the hood to the main filter.

Exhaust Fan

The role of the exhaust fan is to create enough negative pressure or suction to draw in the fumes to the main filter.

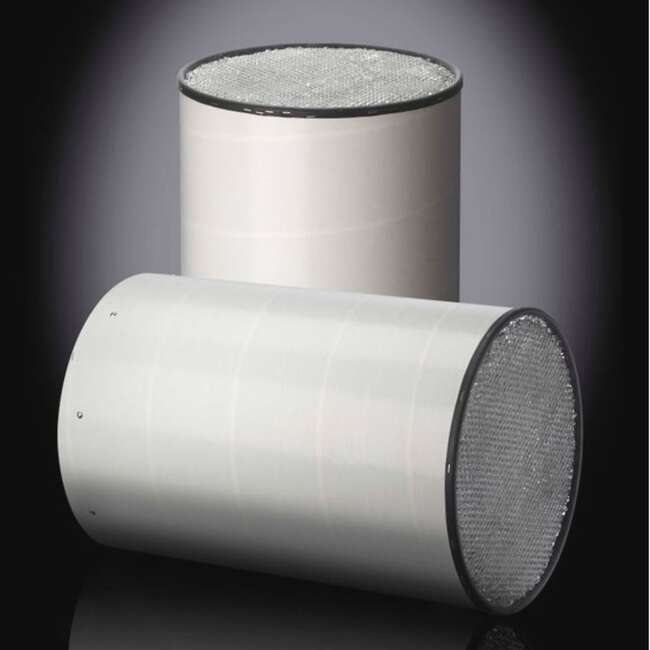

Main Filter

This is the main core component of the welding filter and is responsible for ensuring that clean purified air comes out the other end. It can have numerous components, such as one to remove coarse particles, a main cartridge or a filter element for removing the finer particles, and a HEPA filter or carbon filter to remove the fumes.

Air Outlet

This ductwork removes the clean, purified air, which is either recirculated or sent outside the facility where the welding is taking place.

To know more about high-performance industrial filters, filter elements, and filtration solutions, contact us at Dynamic Filtration Ltd. today. As a leading industrial air filter manufacturer, our collection includes panel filters, pleated air filters, welding filters, custom filters, and much more. Call us at 519-886-0749 for more details.